Mechatronics Engineer – Blink Robotics Systems

Champaign, IL · 2025 – Present

Overview

Architected ROS2/C++/ROS2 automation pipelines for a 4‑DOF robotic platform used in medical research workflows, including deterministic trajectory generation, cycle sequencing, and motor‑controller coordination under strict timing constraints. The system is in development for deployment at the Molecule Maker Lab to autonomously navigate around the laboratory floor, interacting with scientists and test vials.

Concept

Use a compact manipulator paired with an NVIDIA Orin and depth cameras to enable equipment‑grade motion automation by implementing fail‑safe state machines, process interlocks, and fault‑tolerant recovery logic to ensure safe and repeatable operation of robotic manipulation tasks in clinical research settings.

Design Process

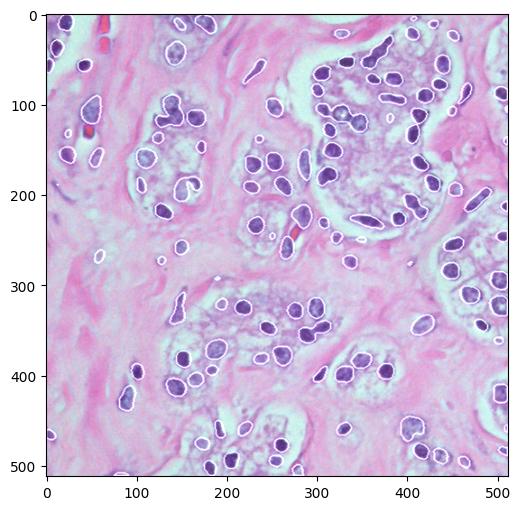

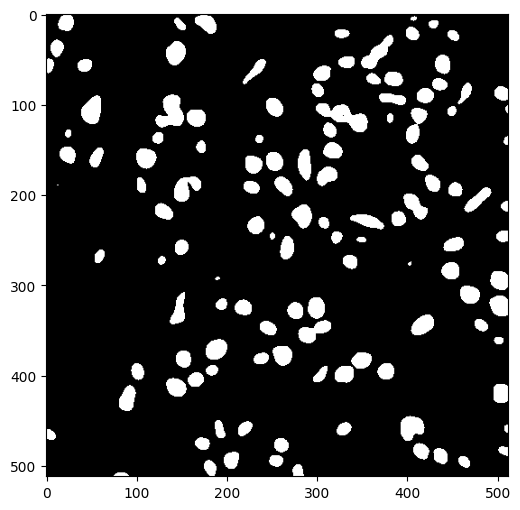

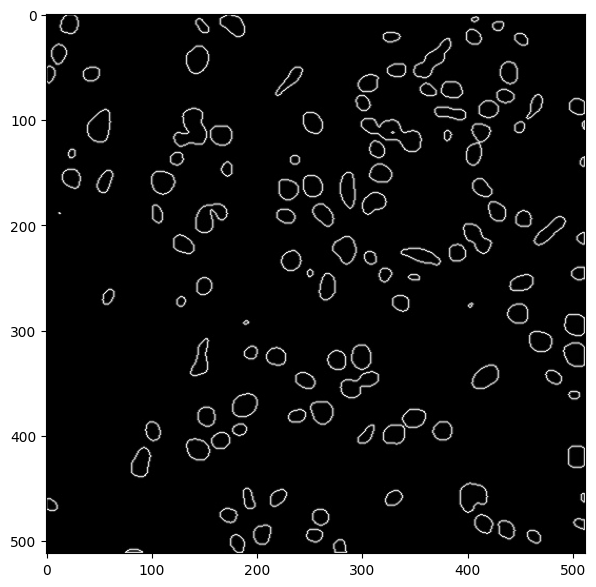

- Implemented SLAM, sensor fusion, and EKF‑based state estimation on NVIDIA Orin using depth cameras and IMUs, enabling autonomous positioning and reliable handoff between automated procedures.

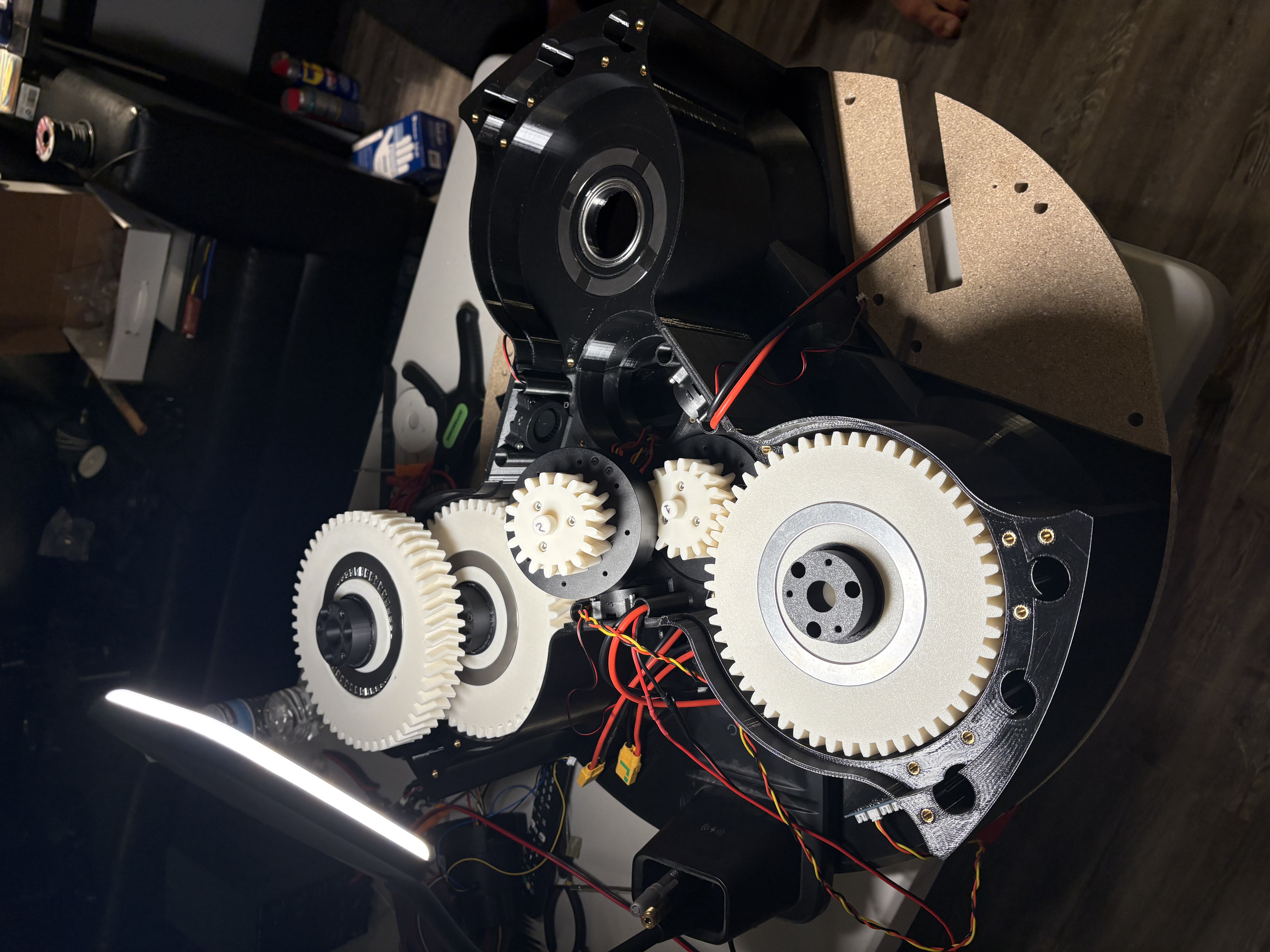

- Designed and fabricated a cycloidal gearbox for QDD actuators, optimizing torque density and mechanical repeatability required for high‑duty‑cycle automated lab instrumentation.

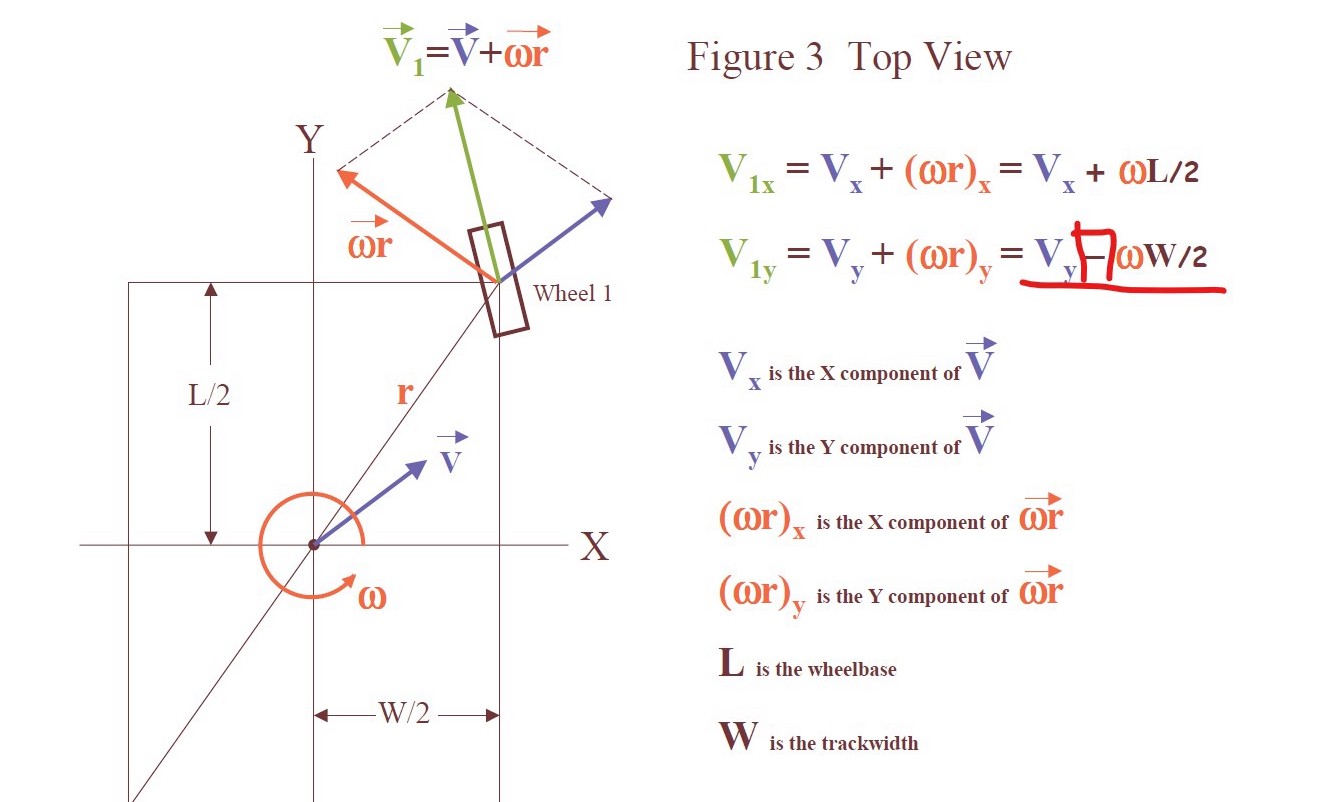

- Developed and benchmarked control and trajectory‑optimization algorithms (PID/PIDF, feedforward, EKF) to regulate torque, manage state estimation in automated workflows, and ensure safe motor performance in autonomous routines.

- Integrated MoveIt motion planning for collision‑free trajectory generation and coordinated multi‑joint movements.

Specifications

Results

- ~40% faster iteration by validating trajectories in simulation first.

- Improved localization accuracy with fused vision + IMU; reduced drift on long runs.

- Bench fault rate reduced via watchdogs and safety state machine.

using NVIDIA Orin and Luxonis depth camera